GS-4000HV Gold Stryker Gold Ore Impact Flail Processing ... - gold mill

2023年8月14日 Our Gold Stryker ® GS 4000HV (High Volume) is a high output / dual adjustable discharge / heavy duty version flail impact rock crusher gold mill that is very

GS-5000 Gold Stryker Gold Ore Impact Flail Processing Rock ... - gold mill

2022年11月2日 GS-5000 Gold Stryker Gold Ore Impact Flail Processing Rock Quartz Crush Mill - Gold-Mill. Our Gold Stryker ® GS 5000HV is a extreme duty high quality

Gold Ore Impact Flail Processing Rock Quartz Crush Mill - gold mill

2023年8月14日 NEW Gold Stryker ® GS-4000 HV (High Volume) is a high output / dual adjustable discharge / heavy duty version flail impact rock crusher gold mill that is very

Secondary Impact Crushers - Stedman Machine Company

The Stedman Grand-Slam secondary impact crushers are built to handle thousands of materials, ores, and chemicals in wet and dry applications. The crushing action of the

Rotor impact mill – crushing of composite materials

The BHS rotor impact mill is a high-performance crusher with a vertical shaft that addresses the needs of the recycling industry. The mill’s unique impeller rotor works together with a

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Crushers. Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or deform the material. During the primary

Industrial Crushing Equipment Pulverizing Mill

Custom Reduction Systems. Stedman has the engineering experience to design, manufacture, and install custom crushing view product. Impact Crushers. An impact

Simulation of particle flows and breakage in crushers using

2015年4月1日 Impact crushers such as hammer mills, VSI and HIS have been simulated. •. Energy absorbed determines breakage with geometric rules for progeny generation. •.

Minerals Free Full-Text Milling Studies in an Impact Crusher

2021年3月20日 A number of experiments were conducted on a laboratory batch impact crusher to investigate the effects of particle size and impeller speed on grinding rate and

Impact Crushers - Cement Crusher Manufacturer - Stedman

Impact crushers are designated as a primary, secondary, tertiary or quarternary rotor crusher depending on which processing stage the equipment is being utilized. Types of

Rotor impact mill – crushing of composite materials

The BHS rotor impact mill is a high-performance crusher with a vertical shaft that addresses the needs of the recycling industry. The mill’s unique impeller rotor works together with a toothed anvil ring to subject the inserted material to severe mechanical stress. Material compounds are crushed and separated selectively, entangled materials ...

Vertical Shaft Impact Crusher - AF Minerals

2024年4月19日 If you have questions, a trained service analyst is always standing by, over the phone or in person, ready to analyze your needs and recommend a complete, long-term, and cost-effective solution. 1-909

How it Works: Crushers, Grinding Mills and

2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the

Stutenroth Impact Mills Crusher Mills, Cone Crusher, Jaw

Production Impact Mills STUTENROTH MILLING MFG. 7611 W. Cornman Rd. • Casa Grande, AZ 85222 (520) 836-5568 • web page: stutenroth.

Understanding the Impact Crusher Working Principle for

2023年2月23日 The impact crusher working principle involves a high-speed rotor that rotates around a horizontal axis. The rotor is equipped with a series of hammers that strike the material as it enters the crushing chamber. The material is then shattered against the hardened steel plates that line the crushing chamber. The shattered material falls through ...

IMPACT CRUSHERS - HAZEMAG

Furthermore, the Compound crusher produces a large amount of minus 10 mm (3/8”), which also reduces the load on the ball mill resulting in considerable savings of operating costs. When you need an Industrial Solution...

Gold Ore Impact Flail Processing Rock Quartz Crush Mill - gold mill

2023年8月14日 Gold Stryker® GS-7000- LD is a very large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation. The Gold Stryker® GS-7000-LD uses a large 25 HP Honda Industrial engine for many years of trouble free use. It can process and crush up to 7 tons in a day, all the way down to #300 mesh through

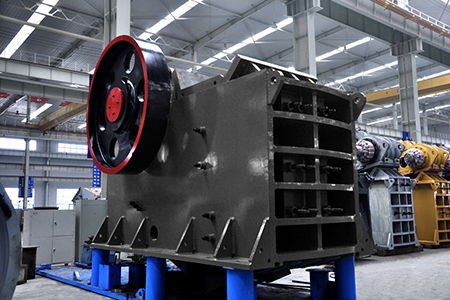

Stone Crusher: Fungsi, Jenis Komponen Pentingnya ...

2023年6月15日 Stone crusher memiliki berbagai fungsi dan manfaat dalam industri konstruksi dan pertambangan, antara lain: 1. Penghancuran Batu. Fungsi utama stone crusher adalah menghancurkan batu besar menjadi ukuran yang lebih kecil. Ini memungkinkan penggunaan batu sebagai bahan bangunan, agregat, atau bahan baku

Gold Ore Rock Crusher Impact Flail Processing Quartz Crushing Mill ...

2023年8月14日 Gold Stryker® GS-7000-LD is a very large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation. The Gold Stryker® GS-7000-LDuses a large 25 HP Honda Industrial engine for many years of trouble free use. It can process and crush up to 7 tons in a day, all the way down to #300 mesh through

Horizontal Shaft Impactor Working And Design - Crusher Mills

Horizontal Shaft Impactor,View Horizontal Shaft Impactor . Horizontal Shaft Impactor is widely applied in mining, transportation, . WORKING PRINCIPLE: This Horizontal Shaft Impactor crushes materials with impact force.

MT 5000 Mobile Hammer Mill - Komplet America

The Komplet MT5000 mobile hammer mill is a tracked compact mill crushing machine, for a fact it is the smallest tracked hammer mill on the market today. It can be loaded via ramps on any truck or trailer, and transported

Impact Mill Crusher Mills, Cone Crusher, Jaw Crushers

Gold Ore Impact Mill,Construction Impact Mills,Mining Roller . Impact Mills are screenless, high-speed beater mills for pulverising and micro-pulverising. The product to be processed is fed to the mill centrally via an inlet box .

How Impact Crushers Work: A Comprehensive

Crushing Equipment / March 11, 2023 / 5 minutes of reading. An impact crusher is a machine used to crush materials by impact energy. It works by feeding the material into a rotating rotor, which is equipped with a series

Barmac® B Series™ impact crushers - Metso

Barmac® crushers are particularly successful in producing road-base, top dressing chip, concrete and asphalt aggregates. In these applications, Barmac® VSI crushers can be operated either in open or closed circuit, depending on the types of aggregates and the specifications required. Manufactured sand production.

Impact crushers - high-quality impactors - Metso

Impact crushers produce high-quality end products efficiently. Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes. As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fast-moving rocks against the walls of the crushing chamber and each ...

Mining Crushers AllMinings

2023年12月5日 Impact Crusher. An impact crusher is a machine used for crushing large rocks, gravel, or stones into smaller pieces. It employs a high-speed rotor with hammers or blow bars that impact the material and cause it to break apart. ... Advantages of a Cage Mill Crusher: Uniform Particle Size: Cage mills are known for producing consistently sized

Impact Crusher Vs. Hammer Crusher: 8 Key Differences

2023年2月15日 Hammer crusher: It has a higher output, up to 3 times that of an impact crusher. Therefore, it is often used in large-scale and high-yield production lines. 6. Different in grain shape. Impact crusher: The crushing ratio is above 50. The discharge is cubic, with uniform particle size, without tension and cracks.

Tactics for Optimizing Crusher and Mill Efficiency: A Guide

2023年5月19日 Crusher efficiency refers to the ability of a crusher to effectively reduce the size of raw material into smaller, more manageable pieces. Benefits include increased production capacity, reduced energy consumption, and improved product quality. Common problems, such as liner wear, overloading, and material hardness, can impact crusher

Hammer Mills for Material Reduction Williams Patent Crusher

Williams Patent Crusher is a leading hammer mill manufacturer. Our industrial size reduction machines can handle any material size reduction job. Choose Williams machinery for efficient pulverizing and long-term service. Hammer mills use midair and impact crushing, grinding, and shredding. This allows them to handle virtually any material.

flail rock mill Mining Quarry Plant

2013年4月1日 GS-4000 is a flail impact gold mill and Perfect for the small Plans To Build Small Flail Mill, process crusher, mining Plans To Build Small Flail Mill 73 Views.